Finished the initial build of this version, version 7 I think

Cx unipivot rev:7

Cx unipivot rev:7 by

anthony cresswell, on Flickr

It's on test at the moment, initial thoughts are actually much more encouraging than I'd hoped.

The glaring problem of the top end seeming recessed seems to have been sorted, although my friend Simons observations on the tilted up bass end are abit more difficult to fathom. This was what he found with version 6, I sent the deck over to his for him to have a listen to it because I needed a second opinion on it and what it was doing. A completely different system, and a different perspective were needed to move forward

The bass seems 'better', not that there is more of it than I can remember, but more structured and tighter. Wether Simon would have to turn the bass amps down on his system again I don't know (he uses massive open baffles with separate amps for each section rather than one amp for the whole speaker), but my feeling is that the rest of the range is more in balance with it. I can't quite tell if the balance is completely right at that end as my big fanes start to roll off at about 45hz, and behave more like hugegreatenormous standmounts than Simons multi way system.

So, changes made to this version.......

From the top, the cartridge mount is brass instead of aluminium, and is epoxied in place rather than being a tight interference fit.

The fingerlift is about half the length it was as I wanted less of the brass rod to be excited and vibrate along with whatever the cart is doing. Not so easy to use, but we shall see how much of a pain in the arse it becomes

It has been assembled in a jig I made for it this time instead of by eye, so everything is much better aligned

The counterweight stub is now also brass, as a result, the wand assembly is marginally heavier than it was

The ring weight in the base of the bearing housing is a couple of grams heavier to compensate for the marginally heavier wand and the affect on the centre of gravity

The bearing pillar is now much better made and is brass again, otherwise its design is the same as it was

The bearing cup itself is now a teeny little sapphire jewel glued into the top of the pillar rather than being machined into the pillar

There is no damping at all in the wand anymore

The arm rest is much more useable, if a bit clunky looking, that can be sorted whenever

The bias guide has been reprofiled to make the string path better with less friction on it

So quite a few changes

Cx unipivot rev:7

Cx unipivot rev:7 by

anthony cresswell, on Flickr

I do need to make a heavier counterweight as the current one is 115g and is hanging off the end of the stub, probably brass again as I don't want to end up with something substantially bigger. The calculated effective mass with an 8g cartridge is 12.6g, this will probably come down abit with a heavier counterweight closer in to the pivot point, I'd estimate it would come down to somewhere close to 11g.

The deck is taking a trip over to mi dads tomorrow, so we shall see what he thinks of it, and hopefully over to Simons again if he has the time to give it a listen. It was most instructive last time it went and definitely helped move the design forward.

Onwards!

Cx mk5 unipivot by anthony cresswell, on Flickr

Cx mk5 unipivot by anthony cresswell, on Flickr Cx unipivot rev:7 by anthony cresswell, on Flickr

Cx unipivot rev:7 by anthony cresswell, on Flickr Cx unipivot rev:7 by anthony cresswell, on Flickr

Cx unipivot rev:7 by anthony cresswell, on Flickr Cx unipivot rev:7 by anthony cresswell, on Flickr

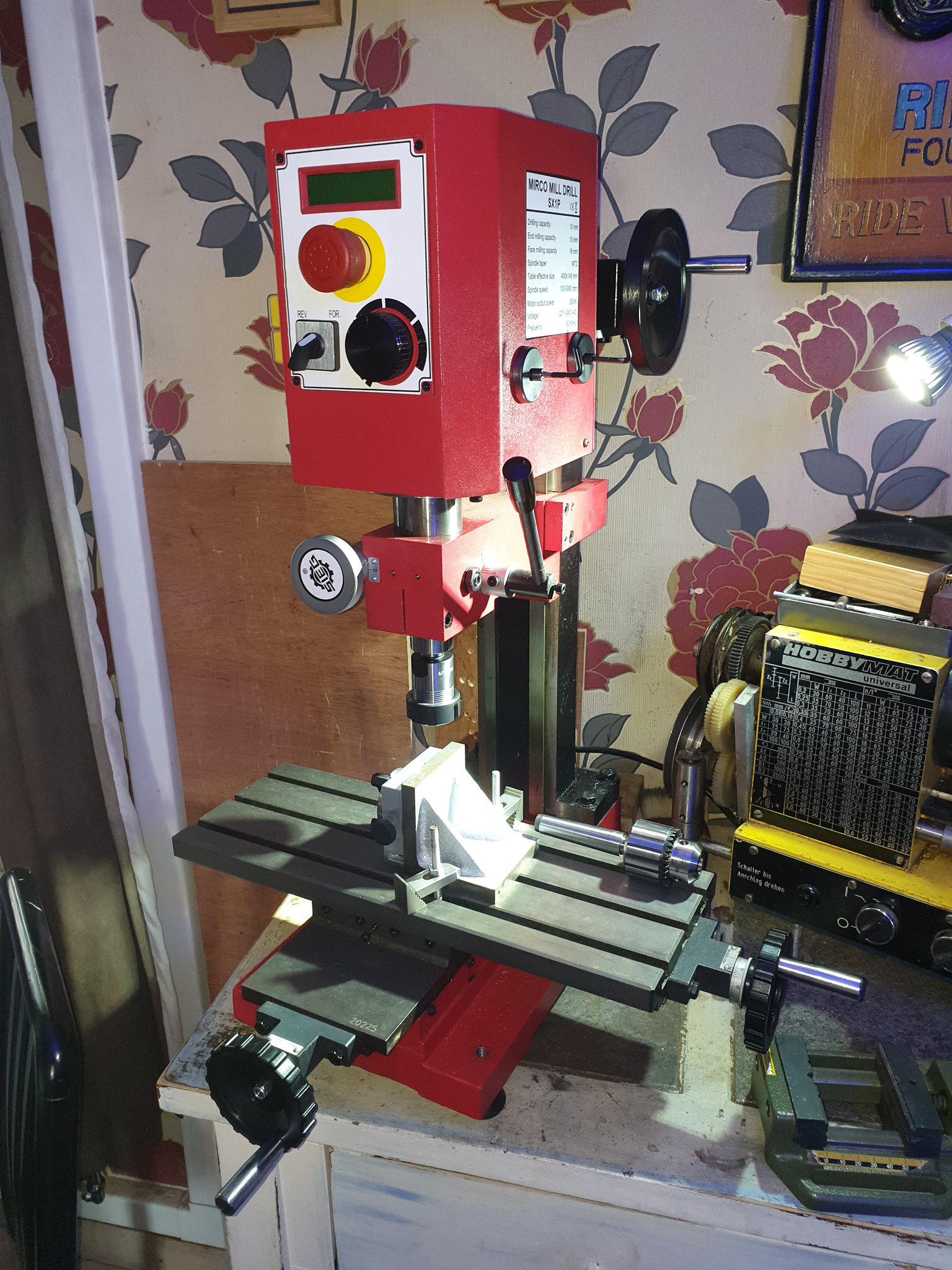

Cx unipivot rev:7 by anthony cresswell, on Flickr Sieg sx1 lp with current accessories by anthony cresswell, on Flickr

Sieg sx1 lp with current accessories by anthony cresswell, on Flickr Cx unipivot rev:7 by anthony cresswell, on Flickr

Cx unipivot rev:7 by anthony cresswell, on Flickr Cx unipivot rev:7 by anthony cresswell, on Flickr

Cx unipivot rev:7 by anthony cresswell, on Flickr Cx unipivot rev:7 by anthony cresswell, on Flickr

Cx unipivot rev:7 by anthony cresswell, on Flickr